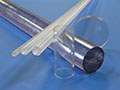

TridentShapes™FDA Compliant Polycarbonate tubing is available off-the-shelf for immediate delivery. Our clear polycarbonate tubing made from Lexan®104 PC resin is high quality, impact-resistant, and well suited for a variety of applications where clarity and strength are critical.

Many industries benefit from Polycarbonate (PC) tube and pipe. A variety of PC products can help improve work environments and increase safety. Polycarbonates are a group of thermoplastic polymers containing carbonate groups in their chemical structures.

Our customers around the globe prefer TridentShapes™ PC tube and pipe because of its many features and benefits such as:

• Abrasion & impact resistance - ideal for industrial applications at many temperatures

• Continuous service temperature 250°F (121°C)

• Dielectric properties & electrical insulation properties

• FDA Compliant

• High tensile, shear & flexural strength

• High quality smooth surfaces

• Lighter & more flexible than stainless steel, stronger & safer than glass

• Optically clear, opaque & multiple color additives available

• Optional UV resistant, flame retardant, flow enhancer & filler additives

• Thermal stability & high heat resistance

• Versatility - variety of sizes & shapes

• Well suited for a variety of applications

TridentShapes™ PC tube is the perfect choice for very demanding applications as it's largely unaffected by humidity changes, greases, oils and acids. Valued for its adaptability, TridentShapes™ PC can be extruded for custom applications, which can be found in multiple industries including:

• Agriculture - components, housings, pipe, sight gauges

• Building & construction - covers, gauges, handles, pipe, rollers, valves

• Electronics - housings, insulators, liners, wire covers

• Energy (oil & gas) - gauges, valves

• Food & beverage - connections, containers, gauges, valves

• Healthcare (medical & pharmaceutical) - fittings, housings, tubing

• Transportation - insulators, liners, relays, wire covers

STOCK POLYCARBONATE TUBING FEATURES:

- Lexan® 104 FDA compliant PC standard in all sizes

- 71 stock sizes, including 8 metric sizes

- High clarity, high impact, water clear

- Convenient minimum purchase quantities

- Available off-the-shelf for immediate shipment