PSU Polysulfone - Round Bar

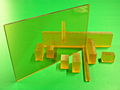

PSU Polysulfone

UDEL® P-1700 Natural Polysulfone (PSU) is a semi-transparent (Amber color), heat resistant, high performance engineering thermoplastic. It offers excellent mechanical, electrical and improved chemical resistance properties relative to polycarbonate. Polysulfone’s properties remain relatively consistent over a broad temperature range, from –150°F (–100°C) to 300°F (100°C). UDEL® Polysulfone is hydrolysis resistant for continuous use in hot water and steam at temperatures up to 300°F. Its flame resistance is UL94 V0 at .177” thickness (4.5mm). UDEL® Polysulfone offers high chemical resistance to acidic and salt solutions, and good resistance to detergents, hot water and steam. In addition, polysulfone is highly resistant to degradation by gamma or electron beam radiation, and offers low ionic impurity levels. Electrical properties of UDEL Polysulfones are stable over a wide temperature range and after immersion in water or exposure to high humidity. UDEL® Polysulfone often replaces polycarbonate when higher temperatures, improved chemical resistance or autoclavability is required. It is commonly used for analytical instrumentation, medical devices and semiconductor process equipment components. Contact customer service for a complete list of physical, mechanical, thermal and electrical properties.

Unit of Measure

| Items |

/Asset/PSU1.jpg /Asset/PSU1.jpg 8061-0250 PSU Polysulfone Round Bar Price/Linear Foot List Price QUOTE

|

/Asset/PSU1.jpg /Asset/PSU1.jpg 8061-0375 PSU Polysulfone Round Bar Price/Linear Foot List Price QUOTE

|

/Asset/PSU1.jpg /Asset/PSU1.jpg 8061-0500 PSU Polysulfone Round Bar Price/Linear Foot List Price QUOTE

|

/Asset/PSU1.jpg /Asset/PSU1.jpg 8061-0625 PSU Polysulfone Round Bar Price/Linear Foot List Price QUOTE

|

/Asset/PSU1.jpg /Asset/PSU1.jpg 8061-0750 PSU Polysulfone Round Bar Price/Linear Foot List Price QUOTE

|

|||||

| Material | N/A PSU | |||||||||

| Color | N/A Amber | |||||||||

| Tolerance | N/A +.005/-.00 in | |||||||||

| Standard Length | N/A 8' ft | |||||||||

| Optional Lengths | N/A | |||||||||

| Specific Gravity | N/A 1.24 | |||||||||

| Hardness, Durometer Shore D | N/A 80 | |||||||||

| Tensile Strength | N/A 10200 psi | |||||||||

| Tensile Modulus | N/A 360000 psi | |||||||||

| Tensile Elongation, Break | N/A 75% | |||||||||

| Flexural Modulus | N/A 390000 psi | |||||||||

| Flexural Strength | N/A 15400 psi | |||||||||

| Impact Strength, Notched | N/A 1.30 ft·lb/in | |||||||||

| Heat Deflection Temperature at 264 psi | N/A 345 ºF | |||||||||

| Dielectric Strength | N/A 425 V/mil | |||||||||

| Flammability Rating (UL 94) | N/A V0 | |||||||||

| ASTM (Resin Spec) | N/A ASTM D 6394 SP0112 | |||||||||

| ASTM (Shape Spec) | N/A | |||||||||

| FDA | N/A 21 CFR177.1655 | |||||||||

| NSF | N/A NSF 51 & 61 | |||||||||

| USP | N/A Call for listings | |||||||||

| ISO 10993 | N/A On request | |||||||||

| Advantages |

N/A

|

|||||||||

| Applications |

N/A

|

|||||||||

| Availability | N/A stock | |||||||||

|

|

||||||||||