Trizod™ OP-ESD Optical Grade Polycarbonate with Static-dissipative/Mar-resistant Surface Coating

Trizod™ MG500 10% Glass-reinforced Polycarbonate

Glass-reinforced polycarbonate is effective in designs where metals, particularly die-cast aluminum and zinc, are commonly used. The addition of glass fibers to polycarbonate increases tensile strength, stiffness, compressive strength, and lower the thermal expansion coefficient. The greater the amount of glass fiber added to the polycarbonate, the greater the effect on each property will be. The coefficient of thermal expansion is reduced by nearly 75%, thus equaling that of some metals. While glass-reinforced has less impact strength than standard grades, it is still tougher and more impact resistant than most other plastics and die cast aluminum.

Trizod™ MG500 is a ?10% glass-reinforced polycarbonate with higher temperature and tensile properties than the unfilled Polycarbonate. Typical property characteristics include superior impact strength, outstanding mechanical strength and stiffness, excellent dimensional stability, and good machinability.

/Asset/Misc Materials1.jpg

Trizod™ MG3412 20% Glass-reinforced Polycarbonate

Glass-reinforced polycarbonate is effective in designs where metals, particularly die-cast aluminum and zinc, are commonly used. The addition of glass fibers to polycarbonate increases tensile strength, stiffness, compressive strength, and lower the thermal expansion coefficient. The greater the amount of glass fiber added to the polycarbonate, the greater the effect on each property will be. The coefficient of thermal expansion is reduced by nearly 75%, thus equaling that of some metals. While glass-reinforced has less impact strength than standard grades, it is still tougher and more impact resistant than most other plastics and die cast aluminum.

Trizod™ MG3412 is a 20% glass-reinforced polycarbonate with higher temperature and tensile properties than the unfilled Polycarbonate. Typical property characteristics include superior impact strength, outstanding mechanical strength and stiffness, excellent dimensional stability, and good machinability.

/Asset/Misc Materials1.jpg

Trizod™ MG3414 40% Glass-reinforced Polycarbonate

Glass-reinforced polycarbonate is effective in designs where metals, particularly die-cast aluminum and zinc, are commonly used. The addition of glass fibers to polycarbonate increases tensile strength, stiffness, compressive strength, and lower the thermal expansion coefficient. The greater the amount of glass fiber added to the polycarbonate, the greater the effect on each property will be. The coefficient of thermal expansion is reduced by nearly 75%, thus equaling that of some metals. While glass-reinforced has less impact strength than standard grades, it is still tougher and more impact resistant than most other plastics and die cast aluminum.

Compared to standard un-filled grades, Trizod™ MG3414 has as much as five times the tensile modulus, more than double the flexural and tensile strength, and up to 65% more compressive strength. Creep limit at 210ºF is as high as 4000 psi under a continuous load and 10,000 psi under an intermittent load. There is a sevenfold increase in fatigue endurance and a 75% drop in the coefficient of thermal expansion.

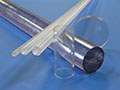

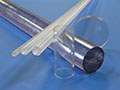

Trizod™ MG Machine Grade Polycarbonate Round Bar

Machine Grade Polycarbonate is a transparent amorphous thermoplastic which offers very high impact strength and high modulus of elasticity. The material has a 290°F (145°C) heat deflection temperature at 264 psi, absorbs very little moisture and resists acidic solutions. These properties, in addition to good electrical characteristics, make Machine Grade Polycarbonate shapes an excellent choice for electrical/electronic applications. Its strength, impact resistance and transparency also make it an ideal material for certain transparent structural applications such as sight glasses and windows.

/Asset/PC16.jpg

Polycarbonate Tube - Clear

General Purpose Polycarbonate sheet is a polished surface, UV stabilized polycarbonate for use in glazing and industrial applications.General Purpose Polycarbonate sheet is used extensively in school and factory glazing for protection against both accidental breakage and deliberate vandalism. In manufacturing environments, this high-impact material excels in applications like machine guards, noise abatement shields, clear work station partitions, freight doors and other in-plant glazing.

/Asset/PC16.jpg