1029 Pulinski Rd Ivyland,

PA 18974

Tel:215-672-5225

Fax:215-672-5582

Email: sales@tridentplastics.com

Website: www.tridentplastics.com

PA 18974

Tel:215-672-5225

Fax:215-672-5582

Email: sales@tridentplastics.com

Website: www.tridentplastics.com

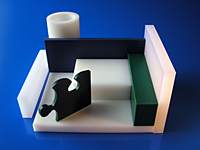

HDPE has a low degree of branching and thus stronger intermolecular forces and tensile strength. HDPE can be produced by chromium/silica catalysts, Ziegler-Natta catalysts or metallocene catalysts. The lack of branching is ensured by an appropriate choice of catalyst (e.g. Chromium catalysts or Ziegler-Natta catalysts and reaction conditions.

| Items |

2600-1251212 High Density Polyethylene - Natural (White) Sheet |

2600-1871212 High Density Polyethylene - Natural (White) Sheet |

2600-2501212 High Density Polyethylene - Natural (White) Sheet |

2600-3751212 High Density Polyethylene - Natural (White) Sheet |

2600-5001212 High Density Polyethylene - Natural (White) Sheet |

|||||

| Sheet Size | N/A 12 x 12 in | |||||||||

| Thickness | N/A 0.125 in | N/A 0.187 in | N/A 0.250 in | N/A 0.375 in | N/A 0.500 in | |||||

| Weight | N/A 0.63 lb/ft² | N/A 0.94 lb/ft² | N/A 1.26 lb/ft² | N/A 1.89 lb/ft² | N/A 2.52 lb/ft² | |||||

| Density (ASTM D792) | N/A 59.88 lb/ft³ | |||||||||

| Hardness - Durometer - Shore D (ASTM D2240) | N/A 67 | |||||||||

| Tensile Strength at Break (ASTM D638) | N/A 4423 psi | |||||||||

| Tensile Modulus (ASTM D638) | N/A 224812 psi | |||||||||

| Elongation - Yield (ASTM D638) | N/A 18 % | |||||||||

| Tensile Elongation, Break | N/A 1350 % | |||||||||

| Flexural Modulus | N/A 166796 psi | |||||||||

| Izod Impact | N/A 1.3 ft·lb/in | |||||||||

| Izod Impact Strength - Notched at 73ºF (ASTM D256) | N/A 3 ft·lb/in | |||||||||

| Tensile Impact Strength (DIN 53448) | N/A 570 ft·lb/in² | |||||||||

| Coefficient of Linear Thermal Expansion | N/A 6.7 x 10-5 in/in/ºF | |||||||||

| Maximum Operating Temperature | N/A 180 ºF | |||||||||

| Volume Resistivity (ASTM D257) | N/A > 1015 ohm·cm | |||||||||

| Optional Sheet Size | N/A 12 x 24 12 x 36 24 x 120 24 x 24 24 x 96 36 x 48 48 x 48 48 x 72 60 x 120 | |||||||||

|

|

||||||||||