1029 Pulinski Rd Ivyland,

PA 18974

Tel:215-672-5225

Fax:215-672-5582

Email: sales@tridentplastics.com

Website: www.tridentplastics.com

PA 18974

Tel:215-672-5225

Fax:215-672-5582

Email: sales@tridentplastics.com

Website: www.tridentplastics.com

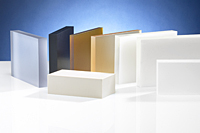

PPS (polyphenylene sulfide) products offer the broadest resistance to chemicals of any advanced engineering plastic. They have no known solvents below 392°F and offer inertness to steam, strong bases, fuels and acids. Minimal moisture absorption and a very low coefficient of linear thermal expansion, combined with a proprietary stress relieving processes, make PPS shapes ideally suited for precise tolerance machined components. In addition, PPS products exhibit excellent electrical characteristics and are inherently flame retardant.

| Items |

8125-02501212 PPS - PolyphenyleneSulfide List Price QUOTE

|

8125-03751212 PPS - PolyphenyleneSulfide List Price QUOTE

|

8125-05001212 PPS - PolyphenyleneSulfide List Price QUOTE

|

8125-06251212 PPS - PolyphenyleneSulfide List Price QUOTE

|

8125-07501212 PPS - PolyphenyleneSulfide List Price QUOTE

|

|||||

| Material | N/A PPS | |||||||||

| Color | N/A off-white | |||||||||

| Thickness | N/A 0.250 in | N/A 0.375 in | N/A 0.500 in | N/A 0.625 in | N/A 0.750 in | |||||

| Sheet Size | N/A 12 x 12 in | |||||||||

| Optional Sheet Size | N/A 12"x48"• 24"x48" | |||||||||

| Tolerance | N/A +only in | |||||||||

| Weight | N/A 1.76 lb/ft² | |||||||||

| Specific Gravity | N/A 1.35 | |||||||||

| Hardness, Durometer Shore D | N/A 85 | |||||||||

| Tensile Strength | N/A 13500 psi | |||||||||

| Tensile Modulus | N/A | |||||||||

| Flexural Modulus | N/A 575000 psi | |||||||||

| Flexural Strength | N/A 21000 psi | |||||||||

| Impact Strength, Un-notched | N/A | |||||||||

| Impact Strength, Notched | N/A .60 ft·lb/in | |||||||||

| Coefficient of Friction, Dynamic | N/A .40 | |||||||||

| Heat Deflection Temperature, 264 psi | N/A 250 ºF | |||||||||

| Maximum Operating Temperature | N/A 425 ºF | |||||||||

| Dielectric Strength | N/A 540 V/mil | |||||||||

| ASTM (Shape Spec) | N/A ASTM D 6358 | |||||||||

| Flammability Rating (UL 94) | N/A V0 (.125") | |||||||||

| FDA | N/A | |||||||||

| Availability | N/A stock | N/A stock | N/A stock | N/A 3-5 days | N/A stock | |||||

|

|

||||||||||