1029 Pulinski Rd Ivyland,

PA 18974

Tel:215-672-5225

Fax:215-672-5582

Email: sales@tridentplastics.com

Website: www.tridentplastics.com

PA 18974

Tel:215-672-5225

Fax:215-672-5582

Email: sales@tridentplastics.com

Website: www.tridentplastics.com

| Items |

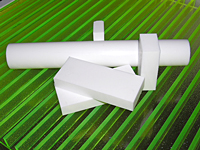

4300-0100 Virgin Electrical Grade PTFE - Molded Tube |

4300-0200 Virgin Electrical Grade PTFE - Molded Tube |

4300-0300 Virgin Electrical Grade PTFE - Molded Tube |

4300-0400 Virgin Electrical Grade PTFE - Molded Tube |

4300-0500 Virgin Electrical Grade PTFE - Molded Tube |

|||||

| Minimum O.D. | N/A 1.750 in | N/A 2.000 in | N/A 2.000 in | N/A 2.500 in | N/A 2.500 in | |||||

| Maximum I.D. | N/A 1.000 in | N/A 1.000 in | N/A 1.250 in | N/A 1.000 in | N/A 1.250 in | |||||

| Minimum Wall Thickness | N/A 0.375 in | N/A 0.500 in | N/A 0.375 in | N/A 0.750 in | N/A 0.625 in | |||||

| Hardness - Durometer (ASTM D1706-59T) | N/A D50-65 | |||||||||

| Water Absorption - 24 hrs, 73°F (ASTM D570-54T) | N/A < 0.01 % | |||||||||

| Static Coefficient of Friction against Polished Steel | N/A 0.05 - 0.08 | |||||||||

| Tensile Strength - 73°F (ASTM D638-61T) | N/A 1000 - 4000 psi | |||||||||

| Elongation - 73°F (ASTM D638-61T) | N/A 100 - 200 % | |||||||||

| Compressive Stress at 1% Deformation - 73°F (ASTM D695-62T) | N/A 600 | |||||||||

| Compressive Stress at 1% Offset - 73°F (ASTM D695-62T) | N/A 1000 | |||||||||

| Maximum Operating Temperature | N/A 500 ºF | |||||||||

| Dielectric Strength - Short Time, 0.080" (ASTM D149-55T) | N/A 600 V/mil | |||||||||

| Volume Resistivity - 0.062" (ASTM D257) | N/A 1.0 x 1017 ohm·cm | |||||||||

| Standard Length | N/A 1' ft | |||||||||

|

|

||||||||||