1029 Pulinski Rd Ivyland,

PA 18974

Tel:215-672-5225

Fax:215-672-5582

Email: sales@tridentplastics.com

Website: www.tridentplastics.com

PA 18974

Tel:215-672-5225

Fax:215-672-5582

Email: sales@tridentplastics.com

Website: www.tridentplastics.com

| Items |

8061-0250 PSU Polysulfone Round Bar Price/Linear Foot List Price QUOTE

|

8061-0375 PSU Polysulfone Round Bar Price/Linear Foot List Price QUOTE

|

8061-0500 PSU Polysulfone Round Bar Price/Linear Foot List Price QUOTE

|

8061-0625 PSU Polysulfone Round Bar Price/Linear Foot List Price QUOTE

|

8061-0750 PSU Polysulfone Round Bar Price/Linear Foot List Price QUOTE

|

|||||

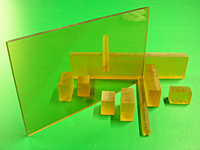

| Material | N/A PSU | |||||||||

| Color | N/A Amber | |||||||||

| Tolerance | N/A +.005/-.00 in | |||||||||

| Standard Length | N/A 8' ft | |||||||||

| Optional Lengths | N/A | |||||||||

| Specific Gravity | N/A 1.24 | |||||||||

| Hardness, Durometer Shore D | N/A 80 | |||||||||

| Tensile Strength | N/A 10200 psi | |||||||||

| Tensile Modulus | N/A 360000 psi | |||||||||

| Tensile Elongation, Break | N/A 75% | |||||||||

| Flexural Modulus | N/A 390000 psi | |||||||||

| Flexural Strength | N/A 15400 psi | |||||||||

| Impact Strength, Notched | N/A 1.30 ft·lb/in | |||||||||

| Heat Deflection Temperature at 264 psi | N/A 345 ºF | |||||||||

| Dielectric Strength | N/A 425 V/mil | |||||||||

| Flammability Rating (UL 94) | N/A V0 | |||||||||

| ASTM (Resin Spec) | N/A ASTM D 6394 SP0112 | |||||||||

| ASTM (Shape Spec) | N/A | |||||||||

| FDA | N/A 21 CFR177.1655 | |||||||||

| NSF | N/A NSF 51 & 61 | |||||||||

| USP | N/A Call for listings | |||||||||

| ISO 10993 | N/A On request | |||||||||

| Advantages |

N/A

|

|||||||||

| Applications |

N/A

|

|||||||||

| Availability | N/A stock | |||||||||

|

|

||||||||||