-

PVC

pvc

-

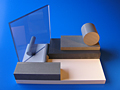

PVC, Type I Sheet

PVC, Type I Sheet

(22)Polyvinyl Chloride / PVC or Vinyl is usually an amorphous thermoplastic material with excellent chemical resistance and dielectric properties, good tensile, flexural and mechanical strength, low moisture absorption, exceptional dimensional stability and good flammability characteristics. The maximum service temperature for PVC is 140°F. The physical properties of PVC can be readily altered by the addition of plasticizers, impact modifiers and other ingredients to develop and enhance specific properties. Generally, there are two basic types of PVC available - Rigid PVC and Flexible (plasticized) PVC. Fabricated by hot gas welding, fusion, butt welding, ultrasonic sealing, die cutting, vacuum forming and thermoforming, and standard machining techniques.

PVC Type I, Grade I - is a normal impact, high corrosion resistant polyvinyl chloride. Because of its exceptional corrosion resistance, it is ideally suited for applications where maximum chemical resistance is necessary. Its high strength-to-weight ratio, cost efficiency, ease of fabrication and eco balance make it the material of choice.

-

PVC, Type I Round Bar

Polyvinyl Chloride / PVC or Vinyl is usually an amorphous thermoplastic material with excellent chemical resistance and dielectric properties, good tensile, flexural and mechanical strength, low moisture absorption, exceptional dimensional stability and good flammability characteristics. The maximum service temperature for PVC is 140°F. The physical properties of PVC can be readily altered by the addition of plasticizers, impact modifiers and other ingredients to develop and enhance specific properties. Generally, there are two basic types of PVC available - Rigid PVC and Flexible (plasticized) PVC. Fabricated by hot gas welding, fusion, butt welding, ultrasonic sealing, die cutting, vacuum forming and thermoforming, and standard machining techniques.

PVC Type I, Grade I - is a normal impact, high corrosion resistant polyvinyl chloride. Because of its exceptional corrosion resistance, it is ideally suited for applications where maximum chemical resistance is necessary. Its high strength-to-weight ratio, cost efficiency, ease of fabrication and eco balance make it the material of choice.

-

PVC, Type II Sheet

PVC, Type II Sheet

(22)Polyvinyl Chloride / PVC or Vinyl is usually an amorphous thermoplastic material with excellent chemical resistance and dielectric properties, good tensile, flexural and mechanical strength, low moisture absorption, exceptional dimensional stability and good flammability characteristics. The maximum service temperature for PVC is 140°F. The physical properties of PVC can be readily altered by the addition of plasticizers, impact modifiers and other ingredients to develop and enhance specific properties. Generally, there are two basic types of PVC available - Rigid PVC and Flexible (plasticized) PVC. Fabricated by hot gas welding, fusion, butt welding, ultrasonic sealing, die cutting, vacuum forming and thermoforming, and standard machining techniques.

PVC Type II, Grade I - is a high impact corrosion resistant polyvinyl chloride. Because of its excellent impact and ductility it is ideally suited for applications that require thermal forming or where the finished product is subject to shock or physical abuse.

-

PVC, Type II Rod

PVC, Type II Rod

(20)Polyvinyl Chloride / PVC or Vinyl is usually an amorphous thermoplastic material with excellent chemical resistance and dielectric properties, good tensile, flexural and mechanical strength, low moisture absorption, exceptional dimensional stability and good flammability characteristics. The maximum service temperature for PVC is 140°F. The physical properties of PVC can be readily altered by the addition of plasticizers, impact modifiers and other ingredients to develop and enhance specific properties. Generally, there are two basic types of PVC available - Rigid PVC and Flexible (plasticized) PVC. Fabricated by hot gas welding, fusion, butt welding, ultrasonic sealing, die cutting, vacuum forming and thermoforming, and standard machining techniques.

PVC Type II, Grade I - is a high impact corrosion resistant polyvinyl chloride. Because of its excellent impact and ductility it is ideally suited for applications that require thermal forming or where the finished product is subject to shock or physical abuse.

-

CPVC Chlorinated PVC Plate

TempRite® Chlorinated polyvinyl chloride, or CPVC, is a thermoplastic which is produced by the post-chlorination of polyvinyl chloride (PVC) resin. CPVC typically contains 65-67% chlorine, compared to 55-57% for standard PVC. Its importance as an engineering thermoplastic is due to its relatively high glass transition temperature, high heat distortion temperature and chemical inertness; it also has outstanding mechanical, dielectric, and flame and smoke properties.

Many CPVC compounds conform to potable water regulations. It is compliant with most international standards and is approved by international agencies including NSF International. It also has excellent resistance to the formation of biofilms. Products made from or including CPVC offer outstanding heat resistance, flame and smoke performance, and weatherability. CPVC can be both downcycled and recycled, and many local recycling protocols allow for CPVC to be integrated into recovery and recycling systems intended for PVC.

• Resistance to corrosion and chemical attack. CPVC often

replaces metals to provide longer service-life in handling corrosive

materials such as aggressive water, mineral acids, caustics and other

aqueous solutions.

• Mechanical strength at high temperatures.

Compared with many thermoplastics, TempRite CPVC has excellent

mechanical strength over a broad temperature range. These long-term

mechanical properties enable CPVC to be used in pressure pipe applications

for up to 50 years at temperatures as high as 203°F (95°C).

• High purity. TempRite CPVC is approved for potable water applications worldwide

by several organizations.

Potable Water Approvals

USA: NSF International

Germany: Deutscher Verein des Gas-und Wasserfaches (DVGW)

UK: Water Research Council (WRC)

Canada: Canadian Standards Association (CSA)

Holland: Keuringsinstituut voor Waterleidingartikelen (KIWA)

These approvals are based on extraction studies which have verified that ingredients such as heat stabilizers do not migrate from CPVC at levels that would be unsafe. Generally, TempRite CPVC compounds do not contain plasticizers, flame retardants, biostabilizers or anti-static agents. Heat stabilizers are added to the resin to prevent decomposition during high-temperature molding or extrusion, but these are not lead- or cadmium-based and present no health hazards.

• Flame resistance and low smoke generation in fires. Because of its low petroleum content, CPVC is self-extinguishing and has a relatively low smoke generation. CPVC has a much higher Limiting Oxygen Index (LOI) value than many

other common materials of construction, thus it will not support combustion under normal atmospheric conditions. Also, any smoke that is generated from CPVC is no more toxic than that from traditional building materials.

TempRite® is a registered trademark of Lubrizol.

-

CPVC Chlorinated PVC Round Bar

Chlorinated polyvinyl chloride, or CPVC, is a thermoplastic which is produced by the post-chlorination of polyvinyl chloride (PVC) resin. CPVC typically contains 65-67% chlorine, compared to 55-57% for standard PVC. Its importance as an engineering thermoplastic is due to its relatively high glass transition temperature, high heat distortion temperature and chemical inertness; it also has outstanding mechanical, dielectric, and flame and smoke properties.

Many CPVC compounds conform to potable water regulations. It is compliant with most international standards and is approved by international agencies including NSF International. It also has excellent resistance to the formation of biofilms. Products made from or including CPVC offer outstanding heat resistance, flame and smoke performance, and weatherability. CPVC can be both downcycled and recycled, and many local recycling protocols allow for CPVC to be integrated into recovery and recycling systems intended for PVC.